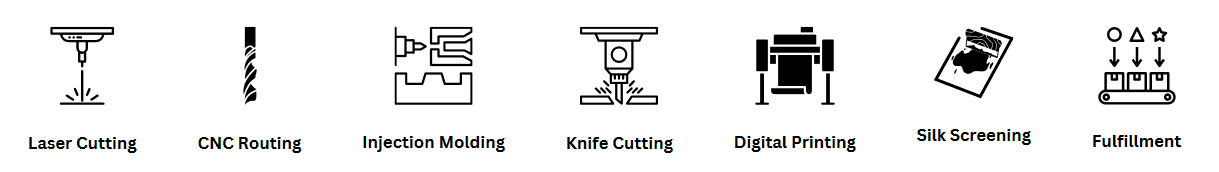

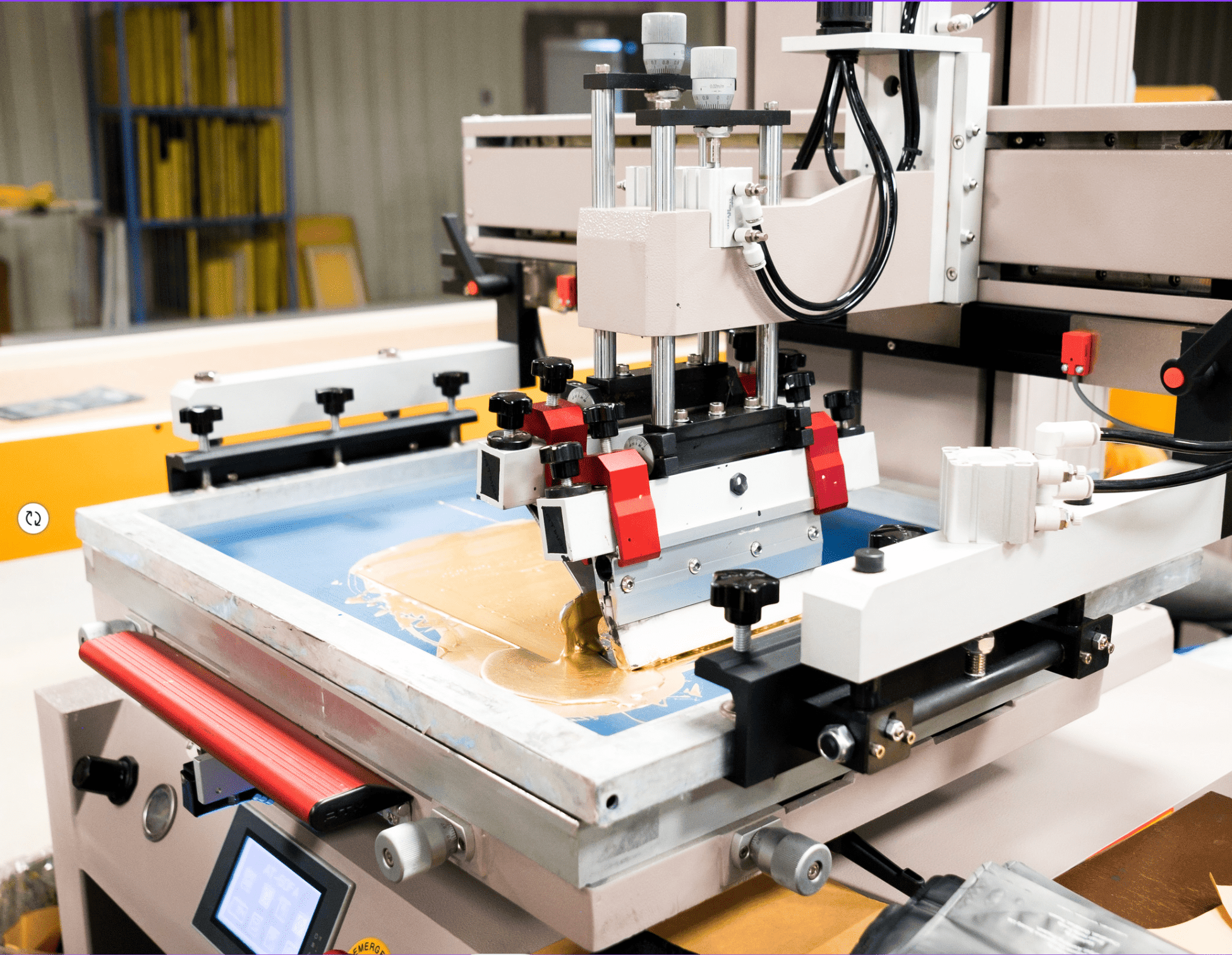

Silk screen printing, also known as screen printing, offers distinct advantages that have solidified its enduring popularity in various industries. One of its key strengths is

its versatility, as it can be applied to a wide range of substrates, including textiles, plastics, paper, and metals. This makes it a preferred choice for producing items like apparel, promotional products, and signage. Another significant advantage is its cost-effectiveness for large-scale production, as the process allows for efficient reproduction of identical designs. Silk screen printing also excels in creating vibrant and durable prints, with the ability to use various types of inks, including metallic and fluorescent options. Its ability to achieve opaque prints on dark backgrounds is another noteworthy advantage. While setup costs and complexity may be higher for intricate designs, the efficiency and longevity of silk screen prints make it a reliable choice for industries seeking durability, versatility, and cost-effectiveness in their printing solutions.